Hello everybody.

Every day I get a lot of questions from different customers about compressors.

- How to calculate compressor capacity for your needs?

- What final pressure must be used?

- What is the best compressor?

- How to choose a compressor for high pressure balloons (receivers)?

- What is the main criterion?

and others.

That’s why I decided to make this short manual on how to choose a compressor and what you need to check before you pay your supplier.

Let’s go…

What is the 1st step?

- Check your consumers and ask your engineers to make calculations?

- Ask supplier’s sales managers for help?

- Or choose a compressor according to your compressor that is already installed or that has to be changed?

Unfortunatelly 99% of people do the same steps.

But when you do compressor’s commissioning you get problems.

Sometimes you don’t have enough capacity. And you can’t fill up your balloons in time.

Sometimes, it is the opposite.

Compressor works only 10 minutes and stays idle all day.

It means you over paid for your equipment.

So…

What is the main mistake?

I am going to explain it an example.

Let’s suppose you have high pressure balloons with 40-400 litres of volume. It could be one balloon or a few.

The main answer we need to know is the final volume we need to fill.

Let’s take 40 litres balloons, 8 pieces.

It means the total volume is 320 litres (or 0.32 m3).

We need 400 bar pressure.

Let’s suppose we need to compress Hydrogen from 5 bar g till 400 bar g.

What is the main criterion?

What do you think is the main criterion?

Possibly you will be surprised but the main criterion is not capacity, not pressure, not volume.

The main criterion is

TIME

I mean what time will we spend if our compressor fills our volume from 5 bar till 400 bar?

So the main question you have to understand the answer is

How many minutes or hours you have to fill volume X with hydrogen

from inlet pressure to final pressure?

Time is the main criterion which will determine your choice.

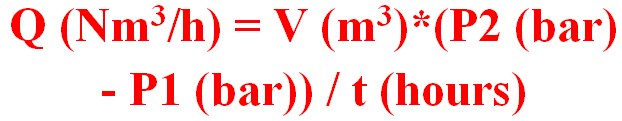

How to calculate capacity if you have pressure, volume and time?

We have the simplest formula for calculations:

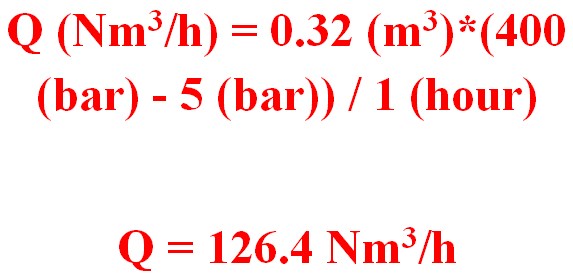

Let’s go back to our example.

We have 8 balloons x 40 litres each. It means we have the total volume 320 litres or 0.32 m3.

The pressure we need to get is 400 bar.

Let’s suppose we need to compress Hydrogen from 5 bar g till 400 bar g.

And we need only one hour to do this task.

After putting all information into formula and making calculations we will need a compressor with 126.4 Nm3/h or more and the final pressure of 400 bar.

Making changes with time (increasing or decreasing) we can find the optimum capacity.

In this case the main criterion will be neither the price nor capacity nor the pressure but the TIME.

If your technology brings you 1 000 000 dollars profit per day and you need to fill your balloons with hydrogen during one hour you have to calculate your compressor because of your technology needs.

All other parametres you need to check during the next step.

That’s all.

I hope this information will help you to avoid the mistakes and save your money.

If you have any questions please feel free to send the comment in the form below.

Regards,

Konstantin Shirokikh