This post is about oil-lubricated high pressure compressor with dryer for hydrogen (H2).

Manufacturer is Gardner Denver (CompAir Reavell in the past).

Yes, it’s not diaphragm compressor.

But, as I wrote before, I would like to share my experience and show to you some examples from my life about high pressure compressors for hydrogen.

The main principles of installation for piston compressors are the same as for diaphragm compressors.

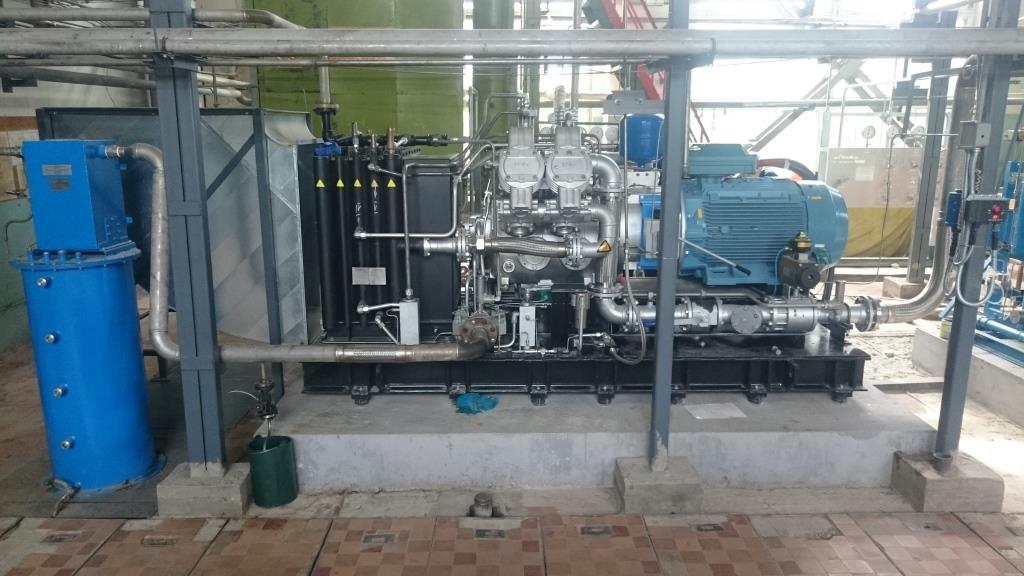

Compressor Reavell 5470 H2

Project description

The customer is the factory from aerospace industry. They started the large reconstruction in 2008 and planned to replace the all old-fashioned equipment.

The main idea was to install air cooled compressor instead of water cooled.

By the way, looking from nowadays, I don’t think that air cooled compressors for 400 bar g are good idea (especially for H2 and He).

I’ve seen a lot of problems with the final stages and valves because of high temperature and not correct cooling.

Anyway we need analyse a lot of factors during the cooling type selection.

Ok, let’s got back to our H5470 H2…

Compressor’s delivery date is 2012.10

1 piece

Description: high pressure oil lubricated piston compressor Gardner Denver (Reavell) H5470 H2 for hydrogen (H2).

400 bar g / 355 Nm3/h – 132 kW

High pressure dryer and filters were included.

Technical parameters are indicated below:

| Model | H5470 H2 |

| Compressor type | oil lubricated piston |

| Inlet pressure (bar g) | 0.04…0.08 |

| Outlet pressure (bar g) | 400 |

| Inlet gas temperature (°С) | -10…+40 |

| Atmospheric dew point (°С) | -65 |

| Capacity (Nm3/h) | 5 |

| Gas | H2 (99.99%) |

| Cooling | air |

| Cooling water temperature (°С) | – |

| Cooling water capacity (m3/h) | – |

| Cooling water pressure (bar g) | – |

| Ambient temperature (°С) | + 1 … + 45 |

| Motor power 400/3/50 (kW) | 132 |

| Real power consumption (kW) | – |

| Control panel | Included as separate unit |

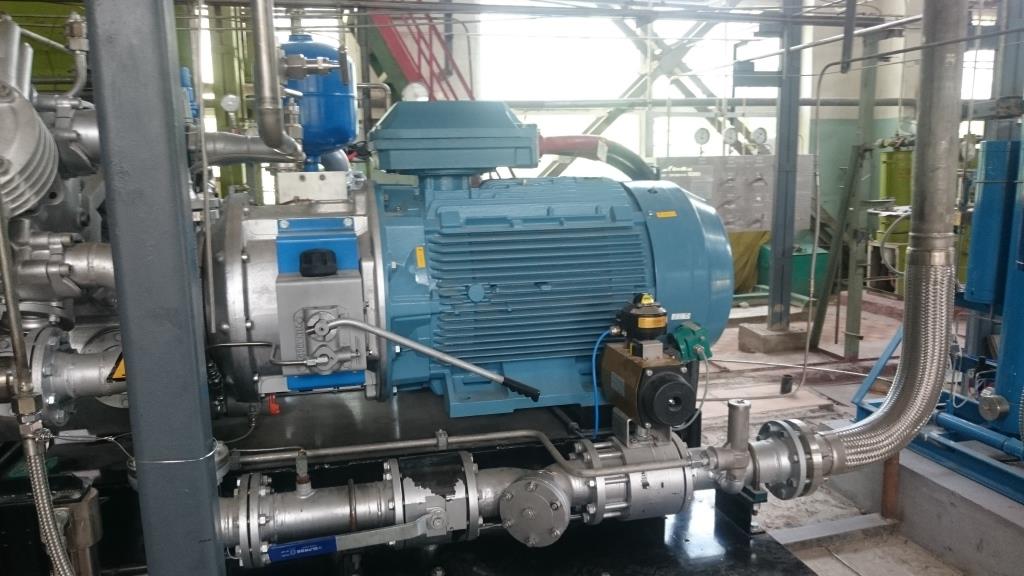

| Implosion protection (by motor) | 1Exd IIC T4 |

| Dimensions LхWхH (мм) | 3356х1897х1750 |

| Weight (kg) | 7250 |

More photos are here:

Hydrogen compressor Reavell 5470 H2

Air cooler for H5470 H2

Air cooler for H5470 H2

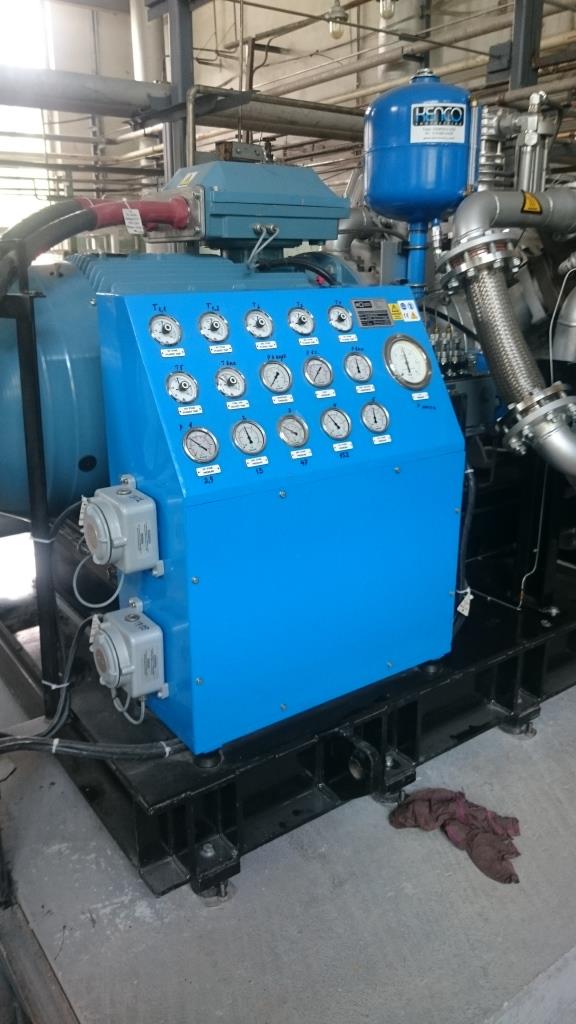

Gauge panel for Reavell H5470 H2

Gauge panel for Reavell H5470 H2

Compressor’s scope of supply

The following was included:

- 5 stages 6 cylinders compressor block

- crank case breather

- electric motor

- direct drive

- inlet gas port

- package anti-vibration mounts

- baseplate with holes

- manometers

- inlet gas pressure sensor

- outlet gas pressure sensor

- crank case oil pressure sensor

- non-return valve for final gas delivery

- safety valve after the 1st stage and for final gas delivery

- interstage and final gas cooler

- terminal box

- electrical connections to terminal box “inside” compressor

- control panel as separate unit for installation in the safe area

- water cooling

- manual oil pressure setting in compressor

Compressor was delivered as totally assembled unit, tested and ready for the commissioning.

Motor

Motor for high pressure hydrogen compressor

Control panel

The starter / control panel is needed for Reavell H5470 H2 in order to function correctly.

Control panel has standard industrial design for installation in a safe area. The panel is for floor / wall mounting. It’s arranged for star delta starting and operation on a 380 volt, 3 phase, 50 Hz electrical supply.

Special demister

Special demister is included. It’s needed for purge and condensate collection.

Demister

Filter/Dryer Package

Fully automatic heatless dual adsorber compressed Hydrogen Dryer under the control of a Remote Logic Step Controller (This panel to be fitted in Safe area) and pneumatically (Supplied from remote 7 bar air supply) operated St.St inlet and purge valves are included.

Hydrogen dryer

Hydrogen high pressure dryer

Purge valves vent through 3 metres high vent stack above dryer assy.

- Complete with Pre Filter.

- Adsorber Filter, both fitted with St.St Auto drain and St.St manual drain valve. Both capable of returning condensate back to compressor de-misting filter.

- After Filter fitted with a manual St.St drain valve. Fitted with Back Pressure Maintaining Valve.

- Dust particle retention to 1 micron.

- Oil removal to 0.005 ppm.

- Outlet Dew point of -65°C assuming inlet temperature of no higher than +40°C

Instrumentation in safe area includes:

Power On/Off lights.

Hours run counter.

Instrumentation on dryer includes:

Safety Patten Adsorber Pressure Gauges

Pilot air pressure gauges for each pneumatically operated valve.

Fully assembled on a Mild Steel frame, interconnected with 12mm O.D. 316 St.St pipe work and 316 St.St compression couplings.

Electric’s 110 V 1Ph 50/60Hz (from safe area)

That’s all.

If you need any help with compressors for hydrogen please don’t hesitate to contact us.

You can send request and will answer during the one working day.

Best regards,

Konstantin Shirokikh